When underground pipes are broken, leak or get blocked, it’s always unwanted. Pipe problems are not just a major inconvenience; they can be expensive and damage property. But, what if we told you that it’s possible to save significant amounts of money, a lot of time and effort, and minimise disruption the next time you have a broken sewer or blocked drain in Sydney? All you need to remember is don’t dig until you talk to Pipe Relining Solutions. This is why:

Pipe Relining Solutions Can Reline Blocked, Cracked, Leaking And Root-Infested Pipes.

Versatile, eco-friendly no dig pipe repair that lasts a long, long time

Pipe relining has fast become the go-to method for low-impact, high-economy pipe and sewer repairs in Australia – and Pipe Relining Solutions has been doing it for longer than anyone else. Both commercial organisations and private homeowners or landlords save huge amounts of money and inconvenience with an innovative and reliable no-dig drain repair solution that negates the need for costly downtime and reinstatement of hard and soft landscaping, roads, or commercial infrastructure.

Pipe Relining Solutions offers a 35-year guarantee, while typical excavation and replacement of pipes with inferior PVC products offers much shorter warranties – sometimes just one year. Pipe reline materials provide a higher flow rate than clay or PVC pipes, and our system works for pipes as small as 50mm or as big as 350mm.

Cost-effective and fast no dig pipe repairs

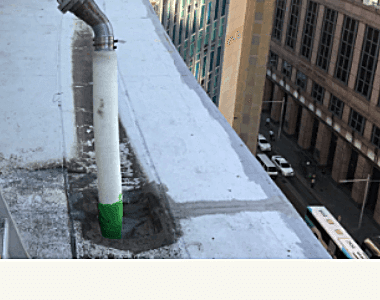

Underground pipe relining repairs mean no, or minimal, expensive, time-consuming digging. We use a high-pressure water jet to clear pipes of debris and then install a durable, resin-impregnated liner using compressed air. We then cure the resin with hot water, forming a watertight seal. The resin hardens quickly, creating a ‘pipe within a pipe,’ so minimal or even no excavation is required compared to traditional pipe replacement. Plus, once the resin is cured, the pipe is ready to use. All of this means pipe repair time gets reduced dramatically. In many cases, we can complete our work in just one day – and all from above ground.

We’re very experienced

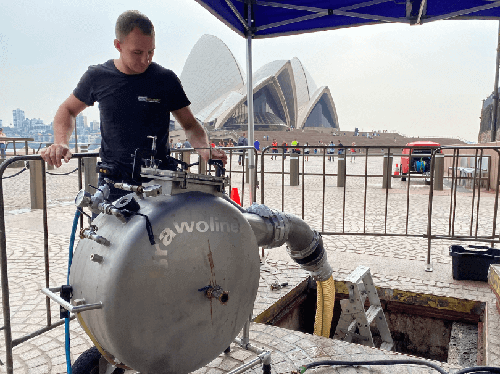

Pipe Relining Solutions is one of Australia’s pipe reline services pioneers, so you’re in the best hands possible – we’ve been pipe relining contractors in Sydney for more than thirteen years. During that time, we’ve helped hundreds of landlords and homeowners solve underground pipe problems such as blocked drains, overflowing sewers and broken stormwater drains. Plus we can complete the bigger sewer and drain repair jobs just as quickly, efficiently, and effectively. Pipe Relining Solutions carries out pipe relining for commercial clients like Qantas, Sydney councils, Westconnex, and the Sydney Opera House.

We have highly trained relining technicians

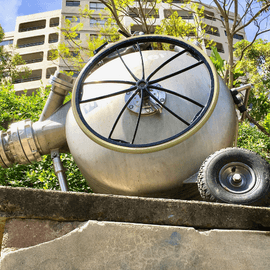

Pipe relining is a specialised service, and although we’re licensed plumbers, it’s all we do every day. That means our guys undertake extensive, intensive specialist training here in Australia and with our product partners in Germany. All Pipe Relining Solutions technicians receive between twelve and eighteen months of training to operate custom vehicles and specialised equipment like robotic cutters and inversion drums.

We use the best trenchless materials and equipment

Even the best pipe relining technicians are only as good as the materials they use, and that’s why we use Brawoliner products. Like most pipe relining materials, Brawoliner is manufactured overseas, but it’s fully approved for harsher local conditions by the Australian Building Codes Board’s Watermark Scheme. Good adhesion is another essential part of effective, long-lasting pipe reline repairs, and Pipe Relining Solutions only uses epoxy resin to ensure a great job.

We put customers and quality first

Customers and quality drive everything we do. Each pipe relining solution we devise is about ensuring a long-term, affordable repair and making our customers happy. Pipe Relining Solutions sets the bar for competitive Sydney pipe relining standards, so if you’re having drain or sewer trouble, be sure to give us a call or fill out the online enquiry form. We love to hear from customers, solve problems, and find ways to make your Sydney pipe reline solution more affordable.

If you’d prefer to learn even more about our innovative pipe repair methods and commitment to excellence first, our website is just as informative. You can read case studies and hear from satisfied customers, read about sewer inspections, and even learn what you need to know before getting a pipe relining quote.

Benefits In a Nutshell